Bundle Rod Heater

Iconic make Bundle rod heater which consists of circular ceramic disc that hold the heating elements. In combination with the radiant tubes which delivers high power, avoid refractory corrosion and avoid the gas impurity in process materials. These design for long life and maintenance free operation. The element can be provided in ferritic alloys up to 1250° C and NiCr alloy up to 1100°C materials.

Components Of Bundle Rod Heaters

- Terminal Rod : Carries the power supply wiring. Usually made of SS 310 or INCOLOY. Number of rods depend upon the supply connection.

- Center Rod : Used to provide central support to the heater. Usually made of SS 310 or INCOLOY. It is longer than the terminal rods.

- Ceramic Disc : Used to encompass all the heating elements to form a bundle. Made of Alumina. Usually of flower shape.

- Fiber Disc : Used to hold the terminal rods and central rod together. Inserted in the cold zone of the heater. Made of ceramic fiber.

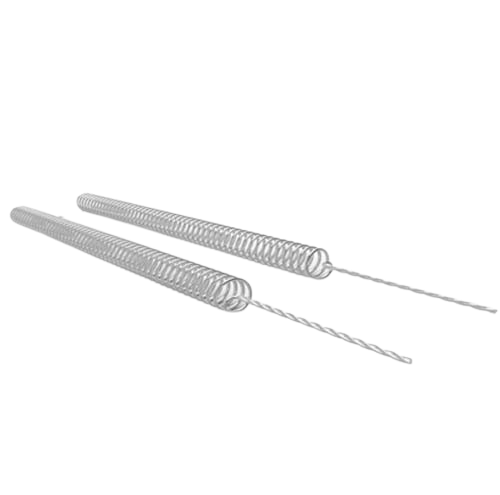

Open Coil Heater

pen coil heating elements have open circuits consisting of coiled resistance wire (usually Ni- Chrome or FeCrAl) fixed onto a supporting element that heats the medium directly. Termed as the most efficient and versatile while also the most economically feasible solution for heating, these elements have fast heat up times that improve efficiency and have been designed for low maintenance and inexpensive replacement parts. When an electrical current is applied to the wire, it gives off heat. The wire is connected to the control panel which regulates the amount of heat provided by the electric heater and fills the tunnel of the air handling unit. Because of the low mass and fast response time, SSR or SCR switching devices are advisable.

They serve as an indirect solution to decrease watt density requirements and prevent heat sensitive materials from breaking down. The heater can be formed into a compact, coiled nozzle heater supplying a full 360 degrees of heat with optional distributed wattage.

The face velocity of the air passing over the open coil elements must not be less than a minimum specified value when the heater is energized. There are three factors that are considered when an appropriate face velocity is calculated, i.e. kW, frame size and heater element type. Sufficient airflow for the required kW in a given frame prevents an overheating condition. Heat must be dissipated away from the heating elements.

The Following Calculation Is Used For Determining Face Velocity:

Face velocity = CFM/Face Area :

Another consideration is the amount of current draw the electric heater will place on the incoming power source. Electric heaters should be divided into individual circuits drawing 48 amps or less. The ‘amp draw’ can be calculated using the kW and voltage of the heater.

Amps = (kW x 1000)/ (Vac x 1.732) :

Attention must also be paid to the geographical area in which the open coil heater is to be located.

D Type Heater

A D-type heater, often referred to in industrial contexts, typically refers to a D-shaped tubular heater or a D-type boiler heater. These heaters are used in various industrial applications for their efficiency and effectiveness in heating processes. Here's a brief overview of both

Applications

- Industrial Ovens and Furnaces: Providing precise and efficient heating for various industrial processes.

- Power Plants: Used in D-type boilers to generate steam for electricity production.

- Chemical Processing: Ensuring consistent and controlled heating for chemical reactions.

- Food and Beverage Industry: Maintaining the required temperatures in processing and storage equipment.